“New Variation” in Lithium-ion Battery Machine Vision vol.2

Lithium-ion battery market situation and its future

- Providing safe, high reliable and stable quality products is the foundation for lithium-ion battery manufactures to steadily transit to the TWh era.

- In the manufacturing process of lithium-ion battery, even a small defect could cause serious problem in each process. It would be a huge problem for manufacturers and users. By installing machine vision system proactively, lithium-ion battery manufactures and materials manufactures could achieve not only improved quality but also high production efficiency and cost reduction.

- Lenses of line cameras which are mainly used in machine vision system is external, the line cameras need big space to secure a certain distance from the scanning objects. In the process like coating or slitting, it is difficult to install line cameras due to the limited space. Also there are some other disadvantages of line cameras such as image distortion and high maintenance cost to deal with adjustments of cameras.

- Lithium-ion battery industry expects an innovative machine vision system. This means it could be a new market opportunity for companies providing distinguished.

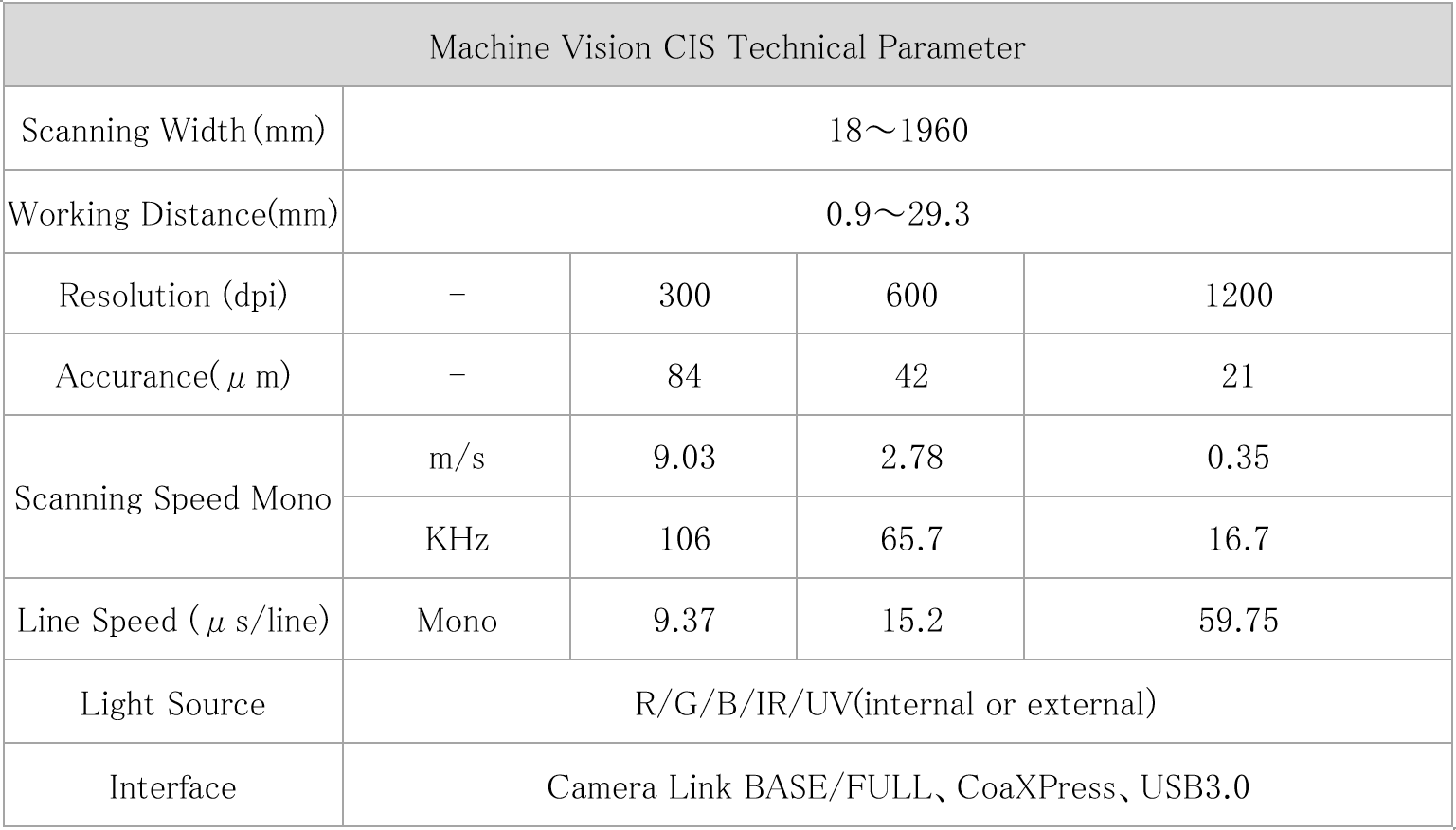

- CIS has 2 types of light source, internal or external light source. These light sources can be adapted to various inspection and measurement situations. CIS can be installed in narrow spaces, which solve the problem of “difficult installation in a limited space” that line cameras have. Users also avoid image distortion or peripheral blurring using CIS because of its advantage, 1:1 image acquisition.

Continuous developing WHEC and CIS Technology

- WHEC CIS is well-known by big machine vision SI in China, and has been installed Lithium-ion battery production line successfully in both China and overseas. With market demands’ increasing, CIS share in lithium-ion battery chain will keep on growing.

- With advanced technology of CIS, the precision of 20μm defect can be detected out in actual application.

- As the technology pioneer of CIS technology, WHEC is keeping on developing application scenarios for Lithium-ion battery inspection. Lithium-ion battery of new energy brings revolution for vehicle, and the developing trend is continuous. Digging the needs of CIS becomes a strategy in such field.

- As a technical strategy, more than 2000dpi CIS is in developing for inspecting higher-precision defect. New interface is also in developing for data transformation with merits of longer-distance and higher-speed.

- From R&D until production, WHEC has built up the whole process which brings competitive power. With independent development of CIS light source, lens, sensors, and core technology, supply chain, WHEC is running successfully.

- With fast growing of machine vision inspection in lithium-ion battery filed, WHEC and its CIS play an important role in this filed.

Article Source: GGLB