“New Variation” in Lithium-ion Battery Machine Vision

Abstract

From the point of innovative technology, Contact Image Sensor (CIS) begins to make a figure, and becomes a “new variation” in machine vision field.

New technics and new technology are bringing new variation to the development of power battery industry.

Face to the large-scale manufacturing time of power battery, the warfare of new technics and new technology has already extended from the core process equipment to the key parts. To help the power battery company to improve product quality, to reduce defect rate, and to improve manufacturing efficiency is not only the common challenges for the industry, but also the opportunity for the new comers to realize corner overtaking.

As the key link who empowers the high quality and intelligence manufacture, the machine vision is developing rapidly, and more and more players are rushing into the track. From the point of innovative technology, Contact Image Sensor (CIS) begins to make a figure, and becomes a “new variation” in machine vision field.

Actually, CIS technology is not a new topic, which has been widely applied in AOI field, but at the same time, it is Weihai Hualing Opto-electronics Co., Ltd (WHEC) that applies this technology to lithium-ion battery field.

①The origin of CIS technology

In 1985, the competition of fax machine market in Japan has been white-hot. In order to break out of this market, Mitsubishi Electric developed contact image sensor used to fax machine at the first time in the world.

With the advantages of compact, high integration, wide field of view, no distortion, high speed, and high resolution, CIS technology stood out from traditional technology of “CCD/CMOS+ optical lens”, which made Mitsubishi fax machines shining in the market.

In 1990, Mitsubishi Electric began to manufacture and sell CIS. After that, CIS technology spread rapidly through fax machine field, and became mainstream technology used in fax machine market all over the world.

The pioneer of CIS technology is Mr. Tetsunori Sawae, who was project leader of CIS technology in Mitsubishi Electric at that time. The CIS technology industrial standard that chaired and formulated by him has been used till today.

In 1995, Mitsubishi Electric founded a joint venture company (SHEC) in Weihai, and Mr. Tetsunori Sawae, as a technology leader, imported CIS technology into China.

In 2003, Weihai Hualing Opto-electronics Co., Ltd (WHEC) was founded, producing CIS for special application with cell line production. Mr. Tetsunori Sawae was appointed as general manager.

Profiting from deep accumulation and creative application of CIS technology, WHEC began to edge burst on the scene. WHEC completed national torch plan, mass production of banknote reading CIS, and large-scale CIS camera for industrial inspection successively.

As CIS technology developed, CIS is continuously applied to backing facility, medical equipment, and industrial inspection market, making up the shortage of CCD in AOI application, and replaced CCD in some subdivision field.

As pioneer and leader of CIS technology, WHEC CIS takes up to 90% market share in Chinese banking facility market, and over 60% share in global market. Meanwhile, WHEC CIS is taking more and more market share in semiconductor manufacture, food safety, biological medicine, and construction materials market, etc.

②Opportunity to access to lithium-ion battery field

After the large-scale application in AOI field, CIS technology draws the attention of leading companies in lithium-ion battery field in Japan and Korea market.

Because of higher request made by power battery companies in product performance, quality management, and production efficiency, the machine vision equipment has gradually become standard inspection configuration in many core processes of lithium-ion battery production.

At that time, the image acquiring unit in cell online inspection usually used single or multiple joint CCD line cameras, while small area inspection or accurate measurement mainly used single CCD area camera.

Therefore, problems also came out. Firstly, because the lens of single area/line camera is independently set, camera has to be set away from the object, which takes some space. At the same time, limited by self-weight and fixing way, cameras are easy to be vibrated influenced by environment around, which will affect the image result.

Secondly, for multiple joint cameras, there is also some problem like image distortion and edge blur, so it needs to adjust the angle of cameras and position of lens constantly, which will also affect the image acquiring efficiency.

Therefore, besides CCD camera application, the leading companies in Korea lithium-ion battery market were searching for new solution for lithium-ion battery electrode and separator inspection, because of which, WHEC has the opportunity to apply CIS technology to machine vision inspection in lithium-ion battery field.

Since 2018, WHEC began to cooperate with leading companies in Korea lithium-ion battery field to develop CIS industrial camera used for lithium-ion battery inspection.

With long-term precise technical identification, WHEC CIS has been successfully applied in lithium-ion battery inspection in some leading companies in Korea lithium battery field, covering all production process from front end process like coating, slitting, winding/lamination to back end cell appearance inspection process.

③CIS advantages for lithium-ion battery inspection

Comparing with area cameras and line cameras, CIS has following advantages:

- Space-saving, easy-adjusting.

With integration of light source, lens, optical sensor chips, CIS is very compact, space-saving in assembly, light-weight, stable-fixing, stronger anti-vibration, etc.

- Macro imaging, high-precision inspection

According to scanning objects, the working distance can be set by

0.9mm~29.3mm for single-sided or double-sided online synchronous inspection.

With linear light source technology for uniform illumination and flexible angle adjusting, defects of coating shedding, pin-hole, foreign matter, breakage, wrinkle, sinking, scratch, edge burr, etc. can be inspected efficiently.

WHEC CIS

3.High-resolution & 1:1 imaging

Effective scanning width of one CIS can be up to 1960mm. CIS has merits with high resolution and 1:1 imaging, by which image distortion can be minimized. Image processing also becomes easy with CIS solution.

4.Customized design

Equipped with built-in light source or external light source that leads to flexible illumination angle, various effective length and outline design, CIS can satisfy various online inspection applications. With advantages of high-integration, high-speed, high-precision, no distortion, etc., CIS can fulfill the core needs of lithium-ion battery inspection. By now WHEC CIS has become a good choice for domestic machine vision system integrators, and has entered into power battery production lines and separator production lines.

④CIS opportunity in lithium battery industry

At present, global power battery makers are marching towards TWh times rapidly. According to expansion plan of lithium-ion battery makers, the production capability can be up to 2TWh by 2025.

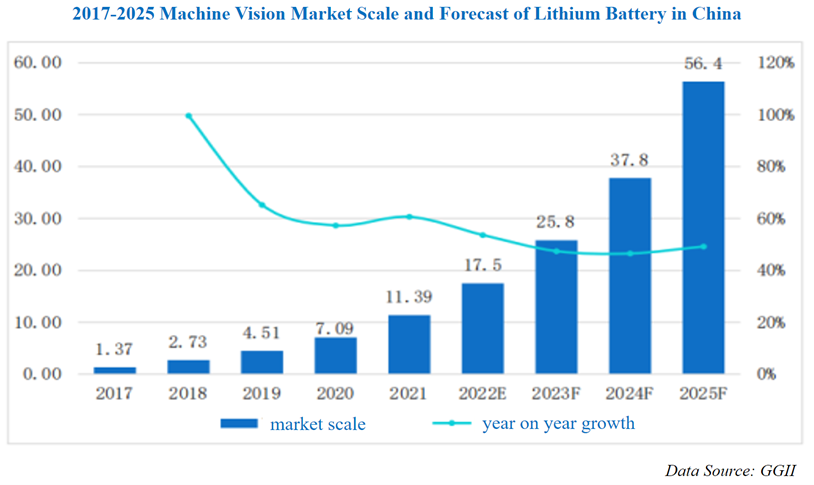

With the background of growing needs of machine vision system in industrial chain, in China the market scale may increase from 0.137 billion CNY in 2017 to 5.64 billion CNY in 2025.

From GWh to TWh, in order to improve the production capacity, product quality, and production efficiency, new technics and new technology are given great expectations.

Once CIS new technology is used by large-scale in machine vision field of lithium-ion battery, the market growth value will be remarkable. This will bring new developing opportunities for WHEC and other CIS makers.

Relying on advantages of function, CIS has been widely used in various application scenarios from fax machine to banking facility, semi-conductor manufacture, food safety, biological medicine, construction materials processing, etc. by now. Horizontal expansion has been realized in various industry.

At the great age of TWh, we believe CIS could have more tremendous opportunities.

Article Source: GGLB